STEINERT GmbH

Booth number: R 30-23

www.steinertglobal.com/applications/mining

About us

The history of STEINERT dates back 136 years: the family-owned, Cologne-based business is one of the world's leading experts in sensor sorting and magnetic separation for waste and metal recycling as well as mining. With 480 employees, STEINERT generates an annual turnover of approximately EUR 180 million. In addition to 50 sales partnerships and joint ventures across the globe, the company has subsidiaries in Germany, Australia, Brazil and the USA.

Since our founding, STEINERT has been a pioneer in mechanical mining separation and processing, e.g. ore sorting equipment. As a leading global manufacturer of advanced sorting and magnet-based systems, we are continually developing new high-tech solutions to meet the challenges of our customers: when it is necessary to protect equipment from tramp iron in material recovery facilities or to process iron ore efficiently, we offer tailor-made magnet systems.

Address

Widdersdorfer Str. 329–331

50933 Cologne

Germany

E-mail: marketing@steinert.de

Phone: +49 221 49840

Internet: www.steinertglobal.com/applications/mining

Contact person:

Jean Makola

E-mail: jean.makola@steinert.de

Phone: +27 82 4458730

Products & Services

Mining separation - magnetic separation and sensor sorting solutions for improved throughput and recovery rates in ore sorting and mineral processing

From traditional and trusted magnetic separation equipment, right through to innovative sensor sorting technologies, we help our customers achieve their goals with sustainable solutions. Whether that is to improve profitability by raising yield, to reduce operating costs, or to improve product purity and even limit environmental impact from their operations, we understand the diverse needs and unique regional necessities which our customers have to deal with. This enables STEINERT to deliver 'value-added' solutions throughout the entire process, from design and consultation through to manufacturing, installation and commissioning services.

Since our founding, STEINERT has been a pioneer in mechanical mining separation and processing, e.g. ore sorting equipment. As a leading global manufacturer of advanced sorting and magnet-based systems, we are continually developing new high-tech solutions to meet the challenges of our customers: when it is necessary to protect equipment from tramp iron in material recovery facilities or to process iron ore efficiently, we offer tailor-made magnet systems.

Our sorting equipment or mineral processing equipment, specially developed for mining applications, enables processes to be better controlled, and through ore sorting even ores that were previously not economically viable, can be efficiently and profitably processed. And our STEINERT technology is even effective in situations in which tailings can be selectively improved in order to be made economically viable.

KSS XT CLI EVO 6.0 for Mining

STEINERT KSS | XT CLI – Advanced XRT + Multi-Sensor Ore Sorting for Mining

Unlock higher yield, lower costs, and sustainable dry processing with this sensor-based sorting solution. The unit is designed as a robust combination sensor sorting system for mining. It harmonizes four sensors:

XRT (X-ray transmission) - detects atomic density contrasts through the particle

Colour - surface colour, texture and reflectance

3D / laser / shape detection - volumetric and morphological information

Inductive (metal detection) - identifies conductive minerals or metal content

By fusing these sensor signals, the system delivers deep sorting depth and is more resilient to material variability than single-sensor machines.

Your benefits:

Lower OPEX via reduced grinding, reagent and water usage

Less tailings volume and downstream load

Higher throughput on the valuable stream

Faster return on investment in low-grade ore environments

STEINERT XSS T EVO 5.0

STEINERT XSS® T EVO 5.0

Density sorting with the STEINERT XSS T EVO 5.0 – via x-ray transmission under the dual-energy principle

For a wide range of sorting solutions and a high level of operational reliability

The STEINERT XSS T EVO 5.0 x-ray sorting system is used for dry density sorting of bulk materials. A transmitting procedure detects material-dependent differences in the absorption of x-rays then classifies and uses them for sorting into density classes.

Steinert customers benefit from the continuous advances made to the sorting machine - especially from the following features in the new EVO 5.0 generation:

MDE stands for Multilayer Data Evaluation - The function takes the place of particularly challenging sorting tasks, such as magnesium detection. Or it solves the issue of detecting and distinguishing composite objects and permits high-resolution object recognition with the classification of various detection tasks running in simultaneous.

AXM - Automatic x-ray monitoring and calibration of the x-ray sensors help achieve consistently high detection and sorting quality. This produces consistently high levels of detection and sorting quality over the entire life of the x-ray components.

HR valve pitch - The high-resolution valve pitch of 6.25 mm sorts even fine material to high levels of precision and thereby improves the sorting performance and cost-effectiveness of processing fine material.

Auto X clean - In the new generation of machines, the X-ray scan area is cleaned automatically. This results in consistently reliable detection and significantly reduces the amount of manual cleaning needed.

STEINERT KSS NR CLI

STEINERT KSS® | NR CLI

The STEINERT KSS | NR CLI sorting system combines modular multi-sensor systems including the NIR range

The solution for ever-changing material separation tasks: the STEINERT KSS | NR CLI sorting machine

This STEINERT sensor-based sorting system combines colour, 3D and metal detection with detection in the near infrared (NIR) range. The modular design allows combination of all four sensors, or only a partial combination.

The logical combination of multi-sensory data collected for each individual object enables a wide variety of tasks to be covered – by just one sorting machine. This combination is therefore mostly integrated as stand-alone solution within a processing concept. The sorting depth is thus effectively extended even for smaller mass flows. Customised equipment and program creation are mandatory.

The combination of detection in the NIR range, by metal sensor or 3D detection provides significant advantages for the processing of complex waste mixtures, such as ASR or RDF.

The STEINERT KSS | NR CLI is a combination of:

C = colour detection

L = laser (3D detection)

I = inductive sensor

NIR = near infrared detection

STEINERT HSDD

Steinert HSDD

High Speed Dry Drums

Recover magnetite with our unique magnetic dry drum solution

Custom designed and built, STEINERT’s magnetic dry drum separators suit various Mining industry applications and processing requirements, which are developed with either our high strength rare earth magnetic element (MIMS) or low intensity magnetic element (LIMS). These High Speed Magnetic Dry Drums can be utilised to produce magnetite concentrate and can be used to process minerals at up to 100% higher capacity than conventional dry drum separators - due to our unique drum construction and feeding arrangements.

This dry technology solution can be used to preconcentrate ferromagnetic particles or eliminate ferromagnetic particles before high-intensity magnetic separation. They can also be utilised to control iron contamination in glass sand production.

Your benefits:

Decreases power consumption of the mill

Decreases wear rates due to lower tonnages needed to be milled for same yield

Reduced amount of gangue material needed to be removed after milling

Enables clients to elect either wet or dry processing

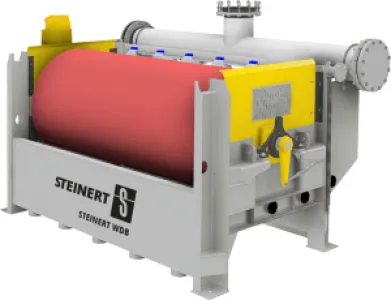

STEINERT WDB

STEINERT WDB-D

Magnetic dewatering drums

Transforming traditional wet ferromagnetic recovery circuits

Custom designed and built, these unique magnetic drum solutions are ideal for Magnetite dewatering plants. They can also be utilised in parallel with existing dewatering equipment.

Traditionally, the concentrate is pumped from the finisher magnetic separator to the thickener. The underflow from the thickener would then be pumped to the filters, and the conveyor would transport the concentrated to the stockpile. The STEINERT WDB-D magnetic dewatering drum solution removes the need to have these concentrate thickening tanks, hence saving space on a mine site or port facility.

These drums consist of powerful rare earth magnets with widths up to 2m - and are available with either our high strength rare earth magnetic element (MIMS) or the low intensity magnetic element (LIMS), with a nominal throughput of up to 70m3/h/m.

Your benefits:

Low capital outlay

Small and flexible footprint

Compact support structure

Operating cost comparable with conventional magnetic separation technologies

Simple commissioning

Reliable and robust mechanical design

Significant redundancy capability plant keeps operating

-thumb.webp)